Project Management Guide

Project Management Guide

What Is Project Management?

What Is a Project?

Why Is Project Management Important?

Project Life Cycle Phases

- Project Initiation

- Project Planning

- Project Execution

- Project Monitoring

- Project Closure

Project Management Methodologies

- Waterfall Project Management

- Critical Path Method

- Critical Chain Project Management

- Agile Project Management

- Scrum Project Management

- Kanban Project Management

- Lean Project Management

- Six Sigma Project Management

- PRINCE2

- PRiSM

- PMBOK Method

Project Management FAQ

The Critical Chain Project Management Method

According to research by the Harvard Business Review, “1 in 6 IT projects turns into a “black swan” with a cost overrun of 200% and a schedule overrun of 70%.”

One of the most disastrous examples coming to mind is KMart’s $1.2 billion failed IT modernization project, which ultimately led to its bankruptcy. The point being, project plans often end up exceeding the budget, timelines, and the planned schedule.

This is where the ‘Critical Chain Method (CCM)’ comes into play. An extension of the ‘Theory of Constraints (TOC),’ as mentioned in the bestseller book, “The Goal,” this method was developed by Dr. Eliyahu Goldratt in 1997.

The Theory of Constraints: “Any system must have a constraint. Otherwise, its output would increase without bound, or go to zero.”

CCM is typically considered to be an enhancement to the ‘Critical Path’ method and focuses on establishing task dependencies as well as resource availability – both of which are essential to follow in order to stay on the project’s critical path. Additionally, this method also integrates a time buffer around these tasks to ensure that the project stays on track and meets the deadlines without any hiccups. In essence, here are the key differences between critical path and critical chain methods:

| Critical Chain Method | Critical Path |

|---|---|

| Multi-tasking is not allowed. | Multi-tasking is allowed. |

| Option of buffers for entire project. | Option of buffers for individual activities. |

| Estimated duration doesn’t include buffers. | Estimated duration includes buffers. |

| Delayed initiation of non-critical activities. | Non-critical activities are initiated as soon as possible. |

| Project typically gets completed ahead of time. | Project may get completed on time or may get delayed. |

| Absence of simultaneous critical activities. | Possibility of simultaneous critical activities. |

The primary aim of CCM is to identify bottlenecks that can lead to wasted time in the project management method. Another key aspect to remember is that it assumes constraints related to each task.

Advantages of Critical Chain Project Management Methodology

CCM or the CCPM (Critical Chain Project Management)method offers a pragmatic approach to completing projects successfully and within the time frame. Here’s a list of its top benefits:

- It allows you to complete projects faster.

- It improves the focus of project managers.

- It offers greater scheduling reliability and helps you utilize the resources in an optimal manner.

- It prevents mismanagement of float/slack.

- It helps you leverage greater predictability, productivity, and speed from your project plans.

- It enhances decision-making for greater project control and offers better scope, cost, as well as schedule performance.

- It gives way to a more feasible and realistic way of project planning.

How This Method Works

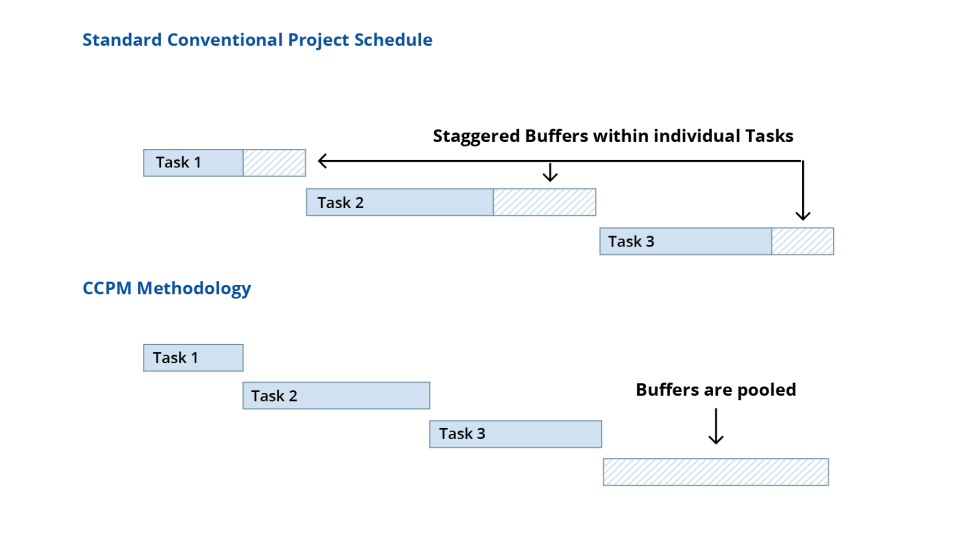

The CCPM method pools task buffers and add them at the end of the critical path.

To start with, let’s understand the list of constraints this method adopts:

- Each task comes with a certain amount of uncertainty.

- Overestimation of task duration ultimately acts as a safety margin to the task and ensures it gets completed on time.

- If the task is completed before the schedule, the saved time cannot be passed on to finish the project early. Alternately, any delays in completing the task will lead to delays in the project schedule.

Moving on, let’s understand the different ways in which you can arrive at ‘Critical Chain Scheduling’ – a method for improving schedules which can be done by:

- Taking the average task time estimates.

- Engaging in backwards scheduling from when a project is about to begin.

- Integrating project buffer management which are mainly of three types:

Resource Buffer: It refers to the virtual tasks inserted just before critical chain tasks, signifying the requirement of critical resources.

Feeding Buffer: It refers to the pooled buffers which branch out into a project’s various critical paths.

Project Buffer: It signifies the total pooled buffer that’s generally added at the end of the project schedule.

Note: Using these buffers eliminates the concept of float/slack, which is rampant in the ‘Critical Path Method.’

Depending on the project’s progress, the critical chain is reworked.

Here are the steps to identify and manage a ‘Critical Chain’ schedule:

Step 1: Start by lowering the activity duration estimates by 50%.

Step 2: Identify the critical chain (the longest chain of the path) and establish resource dependencies after getting rid of resource contentions. The critical chain should be the primary focus of the project manager throughout the project.

Step 3: Place a ‘Project Buffer’ at the end of the project to protect the completion of the ‘Critical Chain.’ Typically, this amounts to 50% of the critical chain path length.

Step 4: Protect the ‘Critical Chain’ from resource unavailability by adding ‘Resource buffers.’

Step 5: Place ‘Feeding Buffers’ on all the paths that feed the ‘Critical Chain,’ to avoid delays related to merging effects.

Step 6: Start gating tasks (tasks that have no predecessors) as late in the process as possible, as it avoids multitasking.

Step 7: Assign resources with activity durations and estimate start times instead of looking at milestones.

Step 8: Ensure roadrunner activity performance and optimal resource allocation to achieve the project’s needs.

Step 9: Finally, use buffer management to control and manage the plan.

This type of project management method works wonderfully well for the manufacturing industry and offers plenty of time to complete projects on time. All in all, it includes both logical and resource dependence, which provides benefits such as reduced project durations for companies by at least 50% in the first pass.